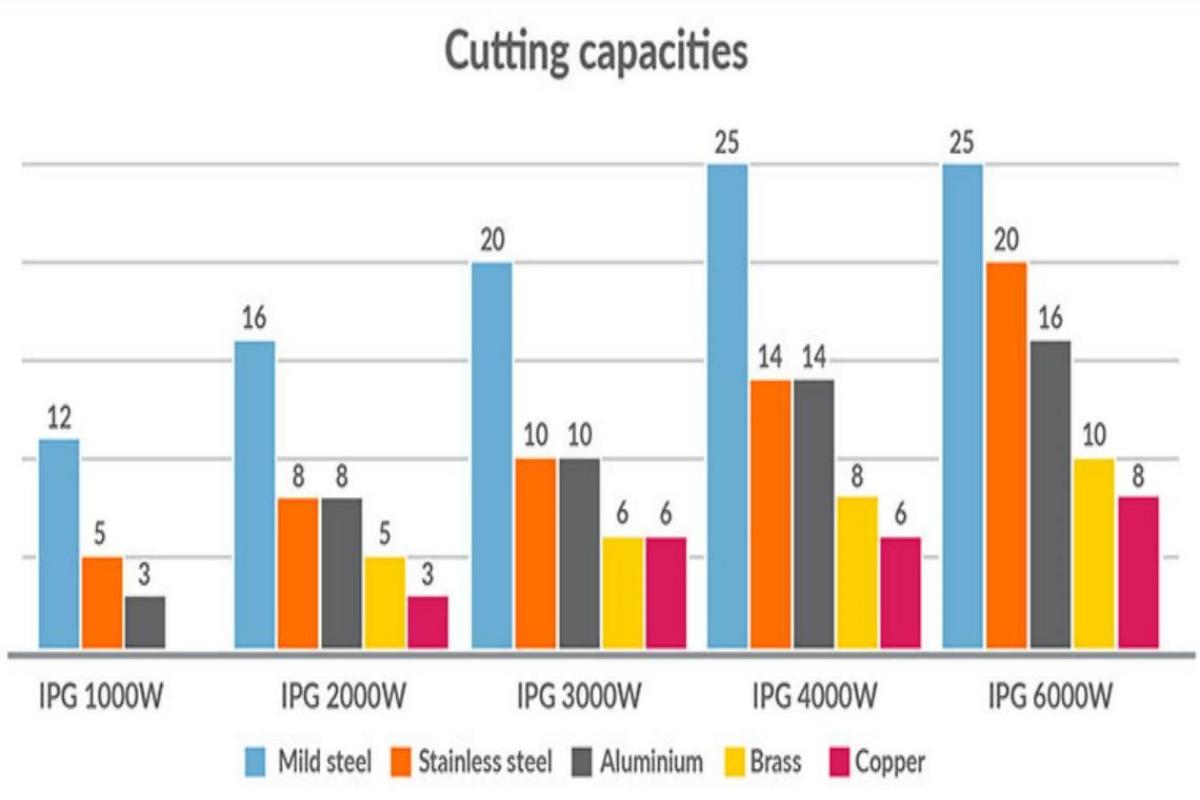

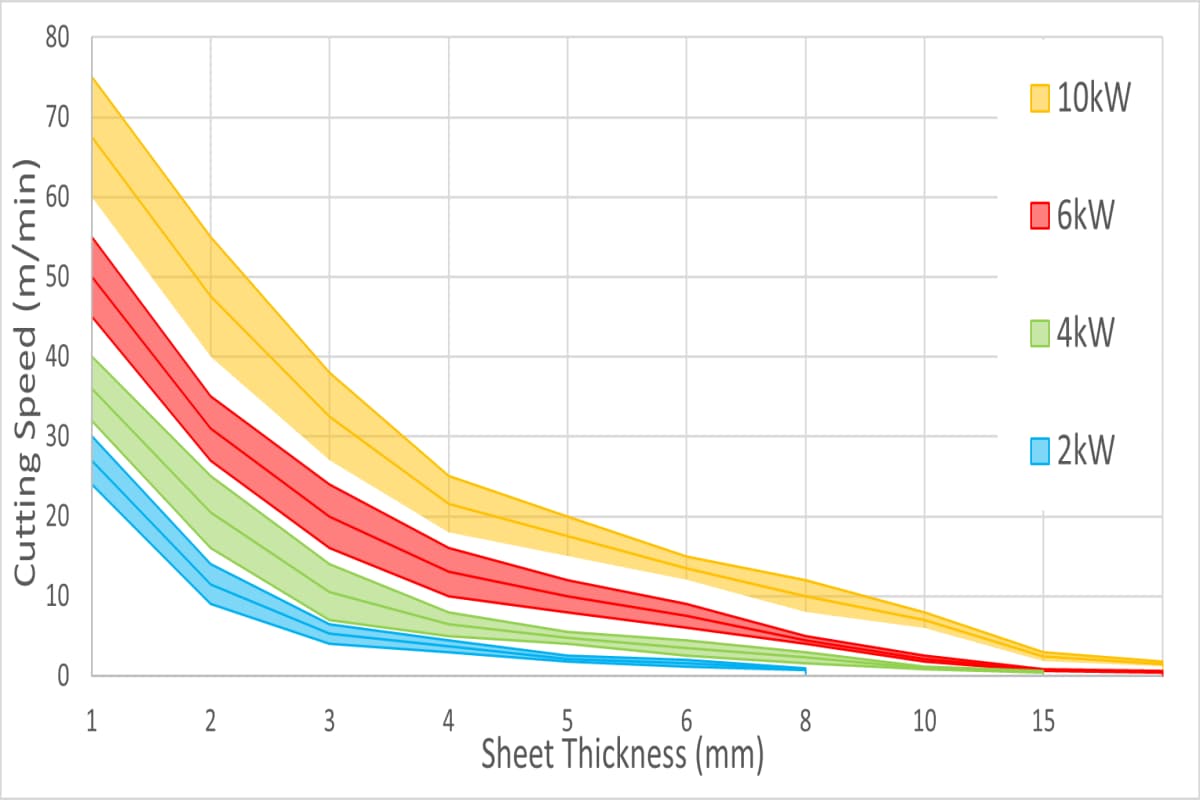

The power selection of fiber laser cutting machines depends on the type and thickness of the materials being cut. The thinner the material, the faster the cutting speed. When a laser cutting machine with the same power cuts different materials, the maximum cutting speed and thickness will vary. This article will list the power, speed, and thickness parameters of various laser-cutting machines. You can refer to the table to select the appropriate laser-cutting machine power. However, cutting speed is not solely affected by power and material thickness. The quality of the optical lens, fiber laser, plate, and gas will also affect the cutting speed. As a general rule, the higher the power, the more expensive the laser-cutting machine, but for most applications, a medium-power laser-cutting machine is sufficient. Therefore, the market share of laser cutting machines in the 1000W to 2000W range is relatively high. Using the chart above, we can compare the parameters of different laser-cutting machines when cutting the same kind of material. For example: Next, we can compare the parameters of the laser cutting machines when cutting different types of materials. For instance: Overall, the chart and comparisons can help in selecting the appropriate laser-cutting machine based on the type and thickness of the material to be cut. If you only need to cut thin plates, a low-power laser cutting machine below 1000W is more suitable. However, if your materials have both thick and thin parts and require mass production, it is recommended to choose a medium- to high-power laser cutting machine. In this way, both thick and thin plates can be processed as long as the parameters are properly adjusted. Laser-cutting machines are widely used in sheet metal processing, automobile manufacturing, construction, and other fields. They can cut a variety of materials, such as wood, acrylic, and plastic, but most are used for metal cutting, such as carbon steel, stainless steel, brass, aluminum, and more. Cutting speed and effect vary with different materials and thicknesses. When cutting highly anti-corrosive materials, such as aluminum and copper, the processing time should not be too long. Auxiliary gas, such as oxygen, is required when cutting iron plates. The laser cutting edge needs to be flat, smooth, and free of burrs and stripes. The cutting speed and the type of auxiliary gas used can affect the quality of the cutting edge. In general, nitrogen and oxygen are the most commonly used auxiliary gases. Nitrogen is an inert gas that does not cause discoloration or oxidation of metals. Using nitrogen to cut metal plates produces a clean and flat cutting edge. Oxygen is suitable for cutting low carbon steel because of its low pressure and high-speed characteristics. Air is suitable for cutting thin metal plates, such as aluminum. The most important component of a fiber laser cutting machine is the fiber laser source. A high-quality fiber laser source has high efficiency, long service life, and low maintenance cost. At present, the most widely used fiber laser source brands are IPG and Raycus. Other components, such as laser cutting head, servo motor, water chiller, air cutting system, control system, stabilizer, etc., also need to be carefully selected. In the article, I have listed in detail the speed and thickness parameters of fiber laser cutting machines with different powers when cutting various materials. By comparing the performance of laser cutting machines with different powers on materials such as aluminum, carbon steel and stainless steel, we can better choose the equipment that suits our needs. Whether it is a 1000W or 12000W laser cutting machine, each power has its unique advantages and application scenarios. I hope this data and analysis will help you make an informed decision when choosing a laser-cutting machine. As a professional sheet metal manufacturer for over 40 years, my company, ADH Machine Tool, provides customers with high-quality laser cutting equipment and solutions. If you are interested in our products, please click on the Product Page for more details. I look forward to working with you. Download the Infographic With High Resolution Desiccant For Electron,Cay Mineral Desiccant,Electronic Mineral Desiccants,Cay Electronic Desiccant XUYI BOTU ATTAPULGITE CLAY CO.,LTD , https://www.xuyibotu.comI. Introduction

II. Fiber Laser Cutting Thickness and Speed Parameters

1. IPG/Carbon Steel/1000W-4000W

1000W 1500W 2000W 3000W 4000W Thickness Speed Speed Speed Speed Speed Material (mm) (m/min) (m/min) (m/min) (m/min) (m/min) 1 9-12 9-12 9-11/18-22 9-12/25-30 9-11/40-50 2 4.5-5 4.9-5.5 5-6 5-6/12-15 5-6/18-22 3 3-3.3 3.4-3.8 3.7-4.2 4-4.5 4-4.5/15-18 4 2.1-2.4 2.4-2.8 2.8-3.5 3.2-3.8 3.2-3.8/8-10 Carbon Steel 5 1.6-1.8 2.0-2.4 2.5-2.8 3.2-3.4 3-3.5/4-5 (O2/N2/Air) 6 1.3-1.5 1.6-1.9 2.0-2.5 3-3.2 2.8-3.2 8 0.9-1.1 1.1-1.3 1.2-1.5 2-2.3 2.3-2.6 10 0.7-0.9 0.9-1.0 1-1.2 1.5-1.7 2-2.2 12 0.7-0.8 0.9-1.1 0.8-1 1-1.5 14 0.6-0.7 0.7-0.9 0.8-0.9 0.85-1.1 16 0.6-0.75 0.7-0.85 0.8-1 20 0.65-0.8 0.6-0.9 22 0.6-0.7 2. IPG/Carbon Steel/6000W-12000W

6000W 8000W 10000W 12000W Thickness Speed Speed Speed Speed Material (mm) (m/min) (m/min) (m/min) (m/min) 1 10-12/

45-6010-12/

50-6010-12/

50-802 5-6/

26-305.5-6.8/

30-355.5-6.8/

38-433 4-4.5/

18-204.2-5.0/

20-254.2-5.0/

28-304 3.2-3.8/

13-153.7-4.5/

15-183.7-4.5/

18-215 3-3.5/

7-103.2-3.8/

10-123.2-3.8/

13-156 2.8-3.2 2.8-3.6/

8.2-9.22.8-3.6/

10.8-128 2.5-2.8 2.6-3.0/

5.0-5.82.6-3.0/

7.0-7.8Carbon Steel 10 2.0-2.5 2.1-2.6/

3.0-3.52.1-2.6/

3.8-4.62.2-2.6 (O2/N2/Air) 12 1.8-2.2 1.9-2.3 1.9-2.3 2-2.2 14 1-1.8 1.1-1.8 1.1-1.8 1.8-2.2 16 0.85-1.5 0.85-1.2 0.85-1.2 1.5-2 20 0.75-1.0 0.75-1.1 0.75-1.1 1.2-1.7 22 0.7-0.8 0.7-0.85 0.7-0.85 0.7-0.85 25 0.6-0.7 0.6-0.8 0.6-0.8 0.6-0.8 30 0.4-0.5 35 0.35-0.45 40 0.3-0.4

3. IPG/Stainless Steel/1000W-4000W

1000W 1500W 2000W 3000W 4000W Thickness Speed Speed Speed Speed Speed Material (mm) (m/min) (m/min) (m/min) (m/min) (m/min) 1 12-15 16-20 20-28 30-40 40-55 2 4.5-5.5 5.5-7.0 7-11 15-18 20-25 3 1.5-2 2.0-2.8 4.5-6.5 8-10 12-15 4 1-1.3 1.5-1.9 2.8-3.2 5.4-6 7-9 Stainless Steel 5 0.6-0.8 0.8-1.2 1.5-2 2.8-3.5 4-5.5 (N2) 6 0.6-0.8 1-1.3 1.8-2.6 2.5-4 8 0.6-0.8 1.0-1.3 1.8-2.5 10 0.6-0.8 1.0-1.6 12 0.5-0.7 0.8-1.2 16 0.25-0.35 4. IPG/Stainless Steel/6000W-12000W

6000W 8000W 10000W 12000W Thickness Speed Speed Speed Speed Material (mm) (m/min) (m/min) (m/min) (m/min) 1 60-80 60-80 60-80 70-80 2 30-35 36-40 39-42 42-50 3 19-21 21-24 25-30 33-40 4 12-15 15-17 20-22 25-28 5 8.5-10 10-12.5 14-16 17-20 6 5.0-5.8 7.5-8.5 11-13 13-16 8 2.8-3.5 4.8-5.8 7.8-8.8 8-10 Stainless Steel 10 1.8-2.5 3.2-3.8 5.6-7 6-8 (N2) 12 1.2-1.5 2.2-2.9 3.5-3.9 4.5-5.4 16 1.0-1.2 1.5-2.0 1.8-2.6 2.2-2.5 20 0.6-0.8 0.95-1.1 1.5-1.9 1.4-6 22 0.3-0.4 0.7-0.85 1.1-1.4 0.9-4 25 0.15-0.2 0.4-0.5 0.45-0.65 0.7-1 30 0.3-0.4 0.4-0.5 0.3-0.5 35 0.25-0.35 40 0.2-0.25

5. IPG/Aluminum/1000W-4000W

1000W 1500W 2000W 3000W 4000W Thickness Speed Speed Speed Speed Speed Material (mm) (m/min) (m/min) (m/min) (m/min) (m/min) 1 10-13 14-18 20-28 30-40 40-55 2 2.8-3.5 5.0-6.0 7-10 15-20 20-25 3 2.0-2.6 4.5-6 8-10 13-15 4 1.4-1.6 2.5-3 5-6.5 7-9 Aluminum 5 1.3-1.6 2.8-3.5 5-7 (N2) 6 0.6-1 2-2.5 3-3.5 8 0.2-0.3 0.8-1.3 1.3-1.8 10 0.5-0.65 0.8-1 12 0.3-0.45 0.6-0.8 14 0.25-0.4 6. IPG/Aluminum/6000W-12000W

6000W 8000W 10000W 12000W Thickness Speed Speed Speed Speed Material (mm) (m/min) (m/min) (m/min) (m/min) 1 60-80 60-80 60-80 55-60 2 28-35 38-43 39-42 35-40 3 18-22 24-26 25-30 25-30 4 10-14 15-17 20-22 20-25 5 8-10 10-12 14-16 13-15 6 4.5-6 6.7-7.5 10-13 10-12.0 Aluminum 8 2.0-2.8 3.2-4 7.8-8.8 5-6.0 (N2) 10 1.2-1.5 2.6-2.8 5.2-7 3.4-4 12 0.7-0.95 1.7-2.0 3.5-3.9 2-2.8 14 1.1-1.3 1.8-2.6 1.3-1.7 16 0.5-0.7 0.8-1.1 1.5-1.9 1.2-1.5 20 0.3-0.35 0.65-0.8 1.1-1.4 0.8-1 25 0.2-0.25 0.5-0.6 0.45-0.65 0.55-0.75 30 0.4-0.5 0.4-0.5 0.3-0.45 35 0.25-0.35 40 0.2-0.3 7. IPG/Brass/1000W-4000W

1000W 1500W 2000W 3000W 4000W Thickness Speed Speed Speed Speed Speed Material (mm) (m/min) (m/min) (m/min) (m/min) (m/min) 1 15-18 22-30 26-40 2 4.5-5.5 10-14 15-20 3 3.2-3.8 5-7 8-12 Brass 4 1.5-1.8 3-4 5-6.5 (N2) 5 0.6-1 2-2.5 3-4 6 1.3-1.5 2.5-3 8 0.5-0.8 1-1.5 10 0.6-0.8 8. IPG/Brass/6000W-12000W

6000W 8000W 10000W 12000W Thickness Speed Speed Speed Speed Material (mm) (m/min) (m/min) (m/min) (m/min) 1 40-50 50-60 50-60 60-70 2 21-24 28-33 34-38 35-40 3 14-16 16-18 20-23 28-32 4 10-11 11-13 14-17 18-24 5 7.0-8.0 8.5-9.2 10-13 13-16 Brass 6 4.0-5.5 6.0-7.0 8.0-9.0 9-11 (N2) 8 2.2-3.0 4.0-5.0 6.0-7.0 6-8 10 1.3-1.6 2.2-2.8 3.0-3.8 4.5-5.5 12 0.7-0.9 1.2-1.5 1.7-2.2 3.1-3.6 15 0.5-0.6 0.7-0.9 1.4-1.8 18 1.2-1.5 20 1-1.3 III. Factors to be Considered in Selecting a Laser-cutting Machine

1. Power of laser cutting machine

2. Material type and plate thickness

3. The smoothness of the cutting edge

4. Laser cutting machine components

IV. Reasons for Differences in Cutting Speeds for Different Materials

Category Factor Description Material Properties Thermal Conductivity Materials with high thermal conductivity, such as copper and aluminum, dissipate heat quickly, making them more difficult to cut. Materials with low thermal conductivity, such as stainless steel, retain heat better,allowing for faster cuts. Reflectivity Highly reflective materials such as aluminum and copper reflect most of the laser energy, making the cutting process less efficient. This requires slower cutting speeds or higher laser power. Melting Point Materials with higher melting points require more energy to reach the melting or vaporization point, which slows down the cutting process. For example, cutting titanium is generally slower than cutting mild steel due to its higher melting point. Material Thickness Thicker materials require more time and energy to cut, resulting in slower cutting speeds. Thinner materials can be cut faster. Material Composition Alloys vs PureMetals Alloys generally have different cutting properties compared to pure metals. For example, cutting stainless steel (alloy) may differ from cutting pure iron because the presence of chromium and nickel affects the cutting process.

V. Conclusion