Laser cutting and engraving technology, as one of the most important technologies in manufacturing, utilizes high-density laser beams to evaporate or melt materials through heat treatment so as to finish high-accurate cutting or engraving. Compared with traditional mechanical cutting and chemical etching methods, laser processing has many advantages, such as high accuracy and speed, wide application, small heat-affected zone, high flexibility and contactless processing. Thanks to their virtues, laser cutting and engraving machines are applied wider worldwide. The statistics show that the global laser cutting machines’ market scale reached 4.5 billion dollars in 2021, with an estimated annualized average growth of 8% in 2028. From the perspective of downstream applications, industries such as automobile manufacturing, consumer electronics, advertising displays, clothing and textiles, and medical devices are all adopting laser processing equipment in large quantities to improve production efficiency and product quality. In China, the laser cutting industry achieved great breakthroughs. It is estimated that by 2025, the market size of China's laser cutting machines will exceed 20 billion yuan. It can be foreseen that laser processing technology will play an increasingly pivotal role in promoting the high-quality development of the manufacturing industry. Therefore, the article will introduce the working principles of laser machine cutting and engraving, their types, advantages and applications, aiming to provide a reference for colleagues in the industry and potential customers. Laser cutting or engraving is a kind of processing method that utilizes the heat action of lasers to finish material removal. Their working principles are similar but differ in processing methods and effects. I will introduce you in the following; before this, let’s view a short video first. Laser cutting utilizes high-power density laser beams on the surface of the workpiece to heat, melt, and evaporate the material in order to cut through the workpiece. The processes are as follows: First step: lasers will generate high-power density laser beams and be focused on the workpiece surface through optical systems. Second step: the focused laser beams will form a high-heat zone on the workpiece surface and melt and evaporate the material. Third step: the CNC control system will control the cutting head to move along the designed paths and finish the cutting process. The key parameters of laser cutting machines include laser power, spot diameter, cutting speed, auxiliary gas pressure, etc. By optimizing these parameters, high-quality cutting can be achieved, such as narrow slits, fewer burrs and Less recasting layer. Laser engraving utilizes relatively low power-density laser beams to selectively remove the workpiece surface to engrave the required patterns or words. Compared with laser cutting, laser engraving commonly doesn’t cut the material thoroughly. Otherwise, it controls laser parameters and scan paths to achieve localized surface engraving. The processes are as follows: First step: convert the patterns or text to be engraved into digital vector or bitmap formats. Second step: laser beams will remove the material selectively while scanning, forming an uneven carving effect. Third step: adjusting parameters such as laser power, scanning speed and line spacing, we control the depth and precision of the engraving. Laser engraving can produce various precise and exquisite patterns, text, and logos on the surface of many kinds of materials. The engraving effect and quality mainly depend on laser parameters, material features, and pattern designs. Craftings need to be improved for different materials and applications to achieve the best effect. Although both laser cutting and engraving utilize the thermal effect of lasers to remove the materials, they differ in processing methods and cutting effects. The main differences are as follows: Processing purposes: laser cutting aims to cut through the materials, while laser engraving aims to engrave on the materials selectively. Laser parameters: laser cutting uses high power density laser beams, while engraving uses relatively low power density laser beams. Processing degrees: laser cutting will penetrate the material, while engraving commonly only removes a layer of material from the surface. Assist equipment: laser cutting requires high-pressure auxiliary gas to blow away the molten material, while engraving usually does not need assist gas. Processing accuracy: the accuracy of laser engraving is typically higher than laser cutting, reaching micro level. Although different from each other, they are used in combination in pragmatic applications in order to meet the requirements of ever more intricate processes. For example, when producing metal nameplates, we can utilize laser cutting to cut out the form and then use laser engraving to engrave the words and patterns of the nameplates. All in all, both laser cutting and engraving utilize the laser thermal effect to remove materials and finish processes. Both have unique characteristics, and they can be optimized and selected based on special processing demands and material qualities. Therefore, a deep understanding of the working principles of laser cutting and engraving helps us leverage the pivotal role of laser processing and improve product efficiency and production quality. Currently, according to the difference of laser, there are two types of mainstream laser machines, including CO2 laser machines and fiber laser machines. Both two have their characteristics and functions in applied sectors. CO2 laser machines emit a wavelength of 10.6 micrometers, which non-metals can absorb well so that CO2 laser machines perform better in non-metal processing. CO2 laser machines are mainly used for cutting and engraving wood, acrylic, textiles and paper. Wood: CO2 lasers can accurately cut wood for furniture, decorations, or other wooden products. At the same time, they are capable of precise engraving, such as patterns and words. Acrylic: In the advertising and decoration industry, CO2 laser machines can accurately cut acrylic boards for making signs, display stands, and lightboxes. Textiles: CO2 laser machines can be used to cut and engrave textiles to make clothes, curtains and other decorations. Paper: In packaging design and making greeting cards and other paper products, CO2 laser machines can perform precise cutting and engraving, offering personalized design solutions. Fiber laser machines emit lasers of 10.6 microwaves which can be absorbed well by metals so they are wise choices for metal processing. Fiber lasers can cut all kinds of materials, such as stainless steel, carbon steel, aluminium and copper. Stainless steel and carbon steel: fiber laser machines can cut these materials fast and accurately, so they are widely applied in automotive, aerospace, and construction industries. Aluminum and copper: although the reflectivity and thermal conductivity of these materials are relatively high, fiber laser machines advanced by technology can cut the materials accurately and are widely used in electronics and the electrical industry. When choosing laser machines, laser power and the sizes of work areas are the top two factors that should be considered. The laser power impacts cutting or engraving speed and thickness, while work area sizes decide the sizes of materials to be processed. Laser power: high-power laser machines are suitable for cutting relatively thicker materials or applications requiring high-speed processing. Low-power laser machines are suitable for thin materials and precise processing. Work area: Large-format laser machines are suitable for large-size materials or mass production, while small-format laser machines are suited for small workpieces or sample making. In addition, the selection of laser machines should also based on material type and specific application requirements. For instance, for non-metal materials that need to be cut or engraved, CO2 laser machines should be chosen; for metal material processing, fiber laser machines should be chosen. Besides, laser power and work areas should also meet the needs of specific production demands. Based on the introduction above, it’s obvious that each type of laser machine possesses unique application sectors and edges. Therefore, the correct selection of laser machines can significantly boost productivity and processing quality. By virtue of excellent performance and broad application prospects, laser cutting and engraving technology is occupying an ever-crucial position in modern manufacturing. Compared with traditional mechanical processing methods, the laser process has edges in many aspects, making itself an ideal choice for the metal and non-metal materials processes. One of the most prominent edges of laser cutting and engraving is extremely high accuracy and great performance in detail. Laser beams can be focused to less than 0.1mm, which, combined with precise CNC control systems, can achieve a machining tolerance of ±0.05 mm in order to meet production requirements for precise components. At the same time, the cutting head can cut and engrave intricate patterns, words and textures flexibly, delivering an extraordinary range for design. Due to the narrow cut silts of laser cutting, normally within 0.1 to 0.5mm, the material wastes are minimized. Compared with traditional mechanical cutting, laser cutting and engraving can save a great amount of raw materials, improving material utilization rates. What’s more, laser cutting and engraving produce high-quality cuts and smooth cutting surfaces that require no secondary processing, saving subsequent polishing and cleaning procedures. Laser cutting and engraving with high efficiency, especially in thin board material cutting, can cut over 100 meters per minute. Controlled by CNC control systems, laser processing procedures can be operated automatically, which greatly improves consistency in productivity and production quality. For instance, laser cutting machines’ loading, unloading, feeding and processing can achieve automation, reducing manual intervention and saving labour costs. Laser cutting and engraving technology are compatible with a wide range of materials, including almost all kinds of metal and non-metal materials. Common cuttable materials incorporate metals, such as carbon steel, stainless copper, aluminum alloy, copper and titanium, and non-metals, such as wood, acrylic, textiles, leathers, glass and ceramics. What’s more, lasers can also handle some hard-to-machine materials, like composite materials and hard alloys. Laser cutting and engraving normally adopt a CNC control system which can directly read vector files of CAD drawings. Totally digital processes can modify designs and optimize parameters. Once appropriate processing parameters are determined, laser machines process repeatedly and steadily so as to ensure the consistency of mass production, which matters in industrial production. Laser processing is suitable for small batches of production and sample making. Having no need for expensive model making, laser cutting and engraving can finish product design validation and iteration rapidly and economically. At the same time, laser engraving can add various personalized patterns, words, and numbers to the workpiece surface, which enables small and medium enterprises and customers to innovate at low costs. Compared with traditional cutting and engraving methods, laser processing is more environmentally friendly. Laser processes free from any chemical solvents or inks, with no waste discharge, meet the requirements of clean production. Meanwhile, contactless processing eliminates tool wear and replacements and noise and vibration pollution, significantly improving the workshop’s environment. Generally, laser cutting and engraving technology possessing edges on accuracy, efficiency, low costs and environmental protection blooms in ever more manufacturing sectors. From industrial production to personalized design and sample making to mass production, laser processing delivers more possibilities and flexibility for product design and manufacturing. The developing and maturing laser technology will bring laser cutting and engraving to more sectors. I’d like to list some pragmatic application sectors and examples for you in the following: Billboards and display boards: laser machines can cut and engrave intricate patterns and words on acrylic, wood and other materials, producing exquisite billboards and display boards. Trophies and souvenirs: laser engravers can engrave personalized patterns, words or pictures on trophies and souvenirs to provide special customized services. Phone and computer enclosures: laser cutting and engraving machines can perform precise cuts on materials such as metal and plastic, creating complex-shaped and accurately sized phone and computer cases. Electronic panel: laser cutters can cut various holes and openings on electronic panels, such as buttonholes, indicator light holes, etc., ensuring precision and aesthetics. Vehicle components: Laser cutting machines can accurately and quickly cut automobile components such as body panels and engine hoods, improving productivity and product quality. Aerospace components: laser cutting machines are capable of highly accurate cutting for high-strength alloy materials used in aerospace, manufacturing core parts, such as airplane shells and engine components. Packaging box: laser machines produce packaging boxes rapidly and efficiently by cutting intricate structures of packaging boxes in cardboard and corrugated paper priorly. Sales display stand: laser cutting machines can cut various shapes of display stand components on materials, such as acrylic and wood, and then the components are reassembled into an attractive, practical point-of-sale display stand. For beginners, understanding laser cutting and engraving technology requires mastering of basic knowledge and operation techniques. ADH Machine Tool has been focusing on high-end laser cutting machines for 40 years, with a wide range of products. But do you know what their secret is? It turns out that ADH Machine Tool not only puts a lot of effort into technological innovation, but also maintains extremely strict control over product quality.No wonder they have won consistent praise from customers. Action speaks louder than words. Quickly log on to the official website of ADH and choose your favourite laser cutters! Or directly contact the sales team, and we will provide you with the most professional selection guidance, making your investment worthwhile. Changshu Enzyme Biotechnology Co., Ltd. , https://www.nmnglutathione.comI.Introduction

II.How does a Laser Machine Cut and Engrave?

Laser-cutting working principles

Laser-engraving working principles

Differences between laser cutting and engraving

III.Mainstream Types of Laser Machines and Their Applications

CO2 lasers for non-metals (wood, acrylic, textiles, paper)

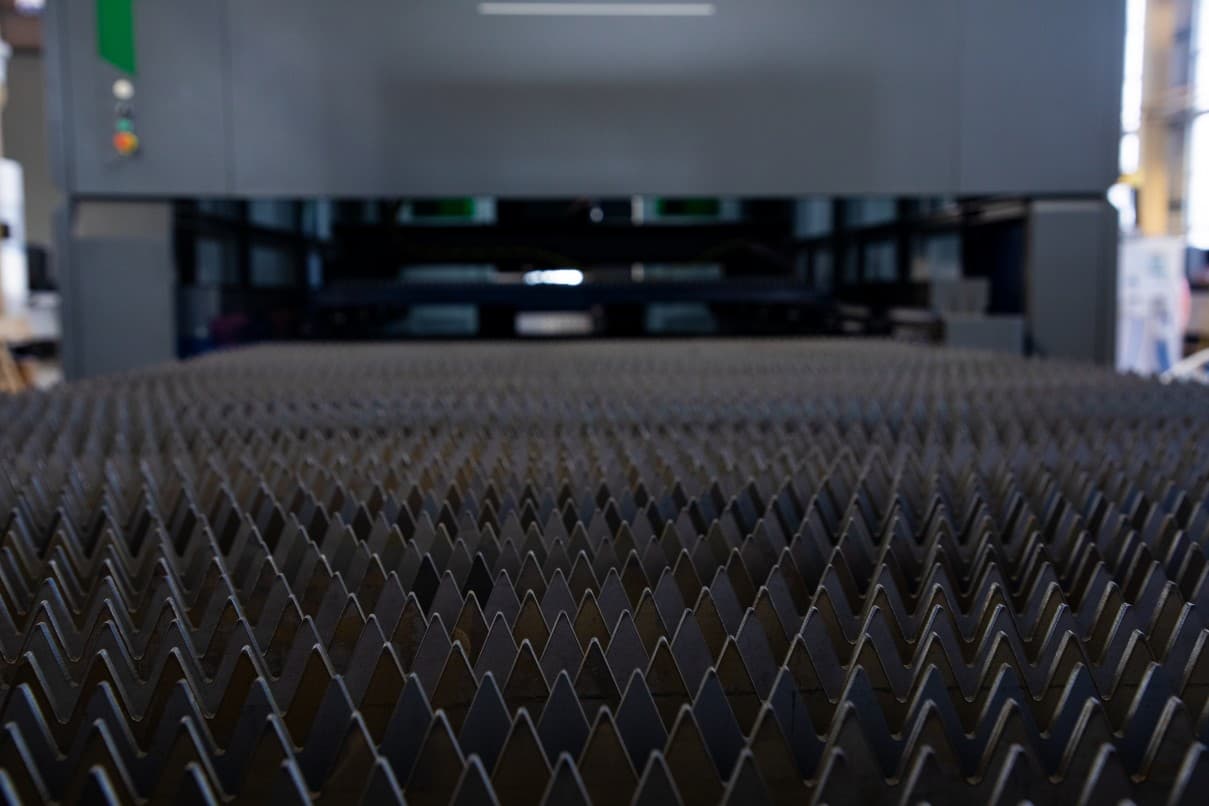

Fiber lasers for metals

Laser power and work area considerations

Matching laser type to material and application requirements

IV.Advantages of Laser Cutting and Engraving

High precision and intricate detail

Minimal material waste and clean edges

Fast processing speeds and automation

Wide range of compatible materials

Digital design input and repeatability

Low-cost prototyping and customization

Environmentally friendly (no chemicals or tools)

V.Applications and Examples

Signage and promotional products

Electronic enclosures and panels

Automotive and aerospace components

Packaging and point-of-purchase displays

VI.Conclusion