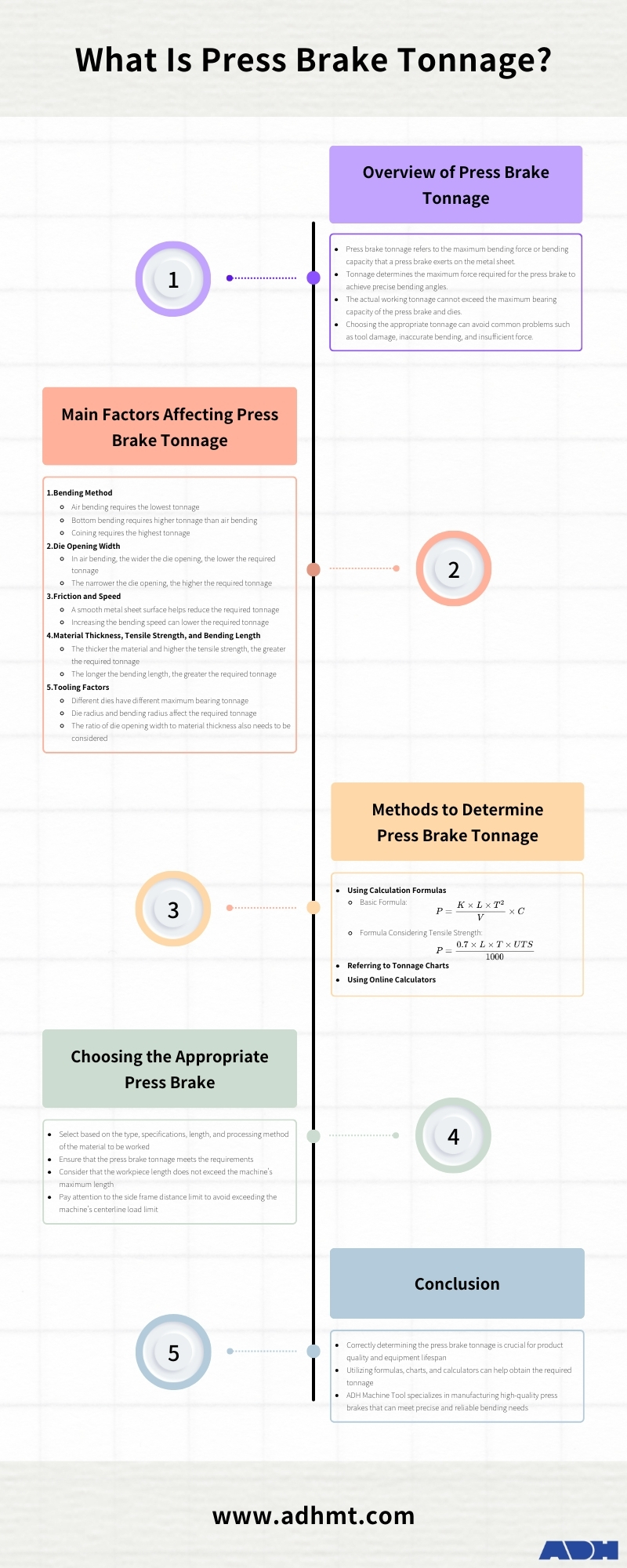

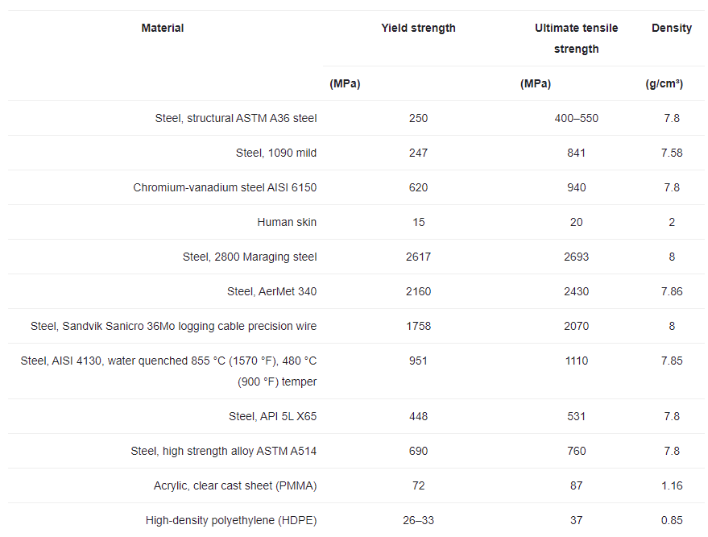

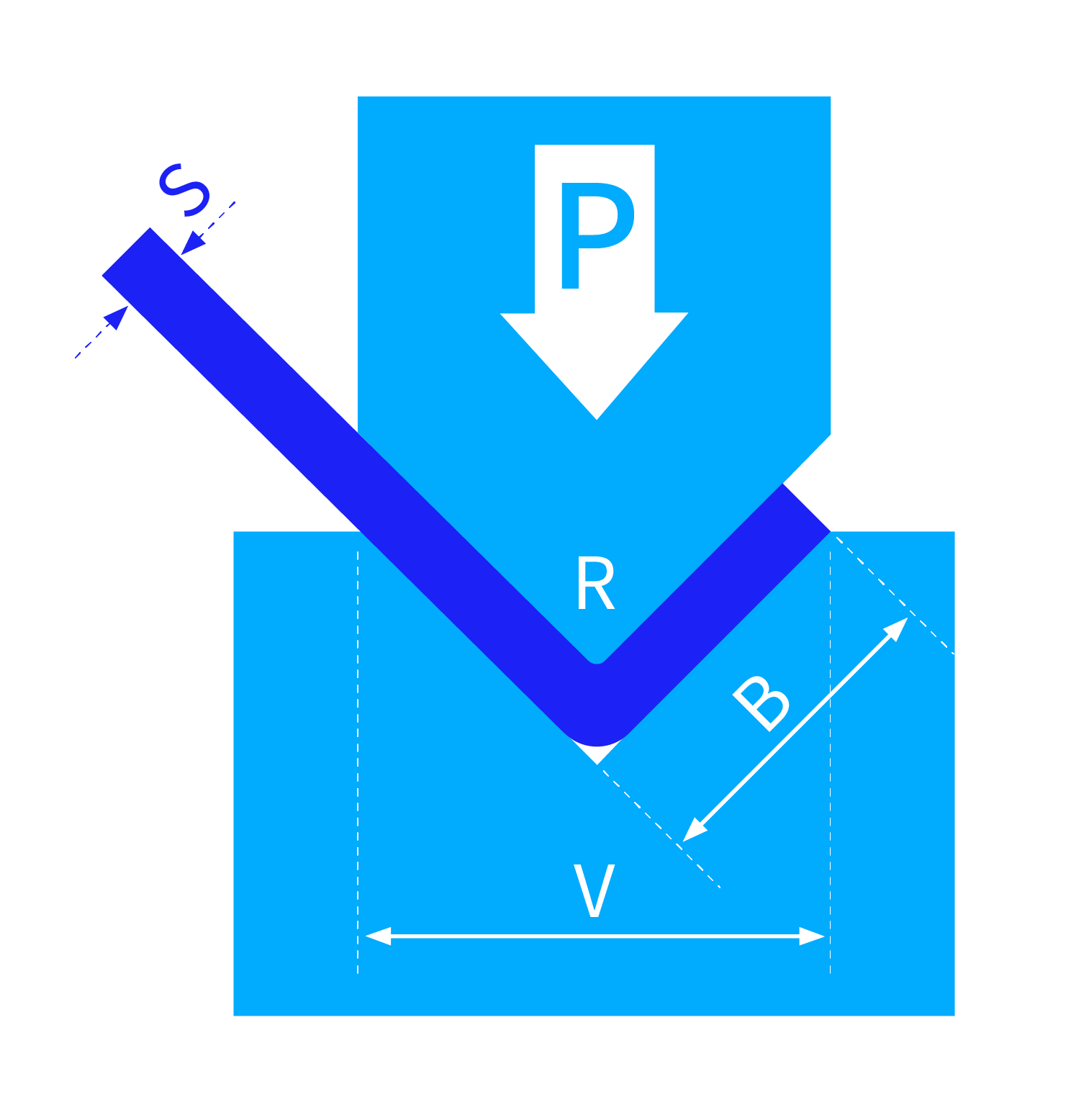

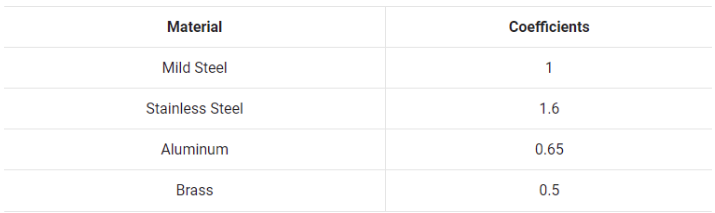

Press brakes are essential machines used in metal fabrication to bend and form sheet metal into various shapes and angles. The basic working principle of a press brake is straightforward: a sheet of metal is placed on a bottom tool called the die, and an upper tool called the punch presses down on the sheet with great force, causing the metal to bend and conform to the shape of the die. Due to their ability to shape metal components precisely, press brakes are highly versatile and are used in a wide range of industries. Some common applications include: In the automotive industry, press brakes are used to form body panels, frames, brackets, and other structural parts. The aerospace sector relies on press brakes to fabricate fuselage sections, wing components, engine enclosures, and more. Construction and infrastructure projects use press-bent parts, such as structural steel sections, roofing panels, and HVAC ductwork. Press brakes also produce components for electronics, medical equipment, home appliances, furniture, and many other products we use every day. Press brake tonnage refers to the maximum press brake bending force or bending capacity required to bend a metal plate using a press brake. The tonnage of the press brake determines the maximum force it can exert on the metal plate to achieve precise bending angles. Additionally, the actual working tonnage cannot exceed the press brake's working capacity and the die's maximum bearing capacity. Choosing the appropriate tonnage can avoid common problems such as tool damage, inaccurate bending, and insufficient force to complete the required bending. The actual tonnage is affected by many factors, such as bending radius, bending method, material thickness, material tensile strength, die ratio, friction between the material and die, the rolling direction of the steel, work hardening, and so on. Generally speaking, the thicker and harder the sheet metal is bent, the higher the working tonnage. Conversely, the thinner the sheet metal, the lower the tonnage required. The force exerted by the press brake on the material is measured in tonnage, which plays a crucial role in ensuring accurate and consistent bending. Tonnage can be defined as the maximum force that a bending machine can exert to form a metal plate, usually expressed in tons per foot or kilonewtons per meter. Each press brake has a different threshold or rating for the maximum force it can generate, and selecting the appropriate tonnage for each application to avoid damage to the machine, tools, or materials is crucial. The calculation of the press brake tonnage is mainly based on factors such as metal plate thickness, bending length, and V-shaped opening width. The press brake tonnage calculator can be used to determine the force required for a specific task. It is crucial to understand the various units of measurement used to measure tonnage capacity, as the calculation methods may vary. The example formula for tonnage calculation is based on AISI 1035 cold-rolled steel with a tensile strength of 60000 PSI. In addition to tonnage, other factors such as mold angle, K-factor, and tool compatibility also play an important role in achieving precise and smooth bending. When setting up and operating the bending machine, these factors must be considered to ensure consistent results and maintain the bending process's efficiency. Multiple methods exist for measuring the press brake's tonnage, and understanding the most commonly used measurement units for tonnage capacity is a crucial first step. The press brake's tonnage can be calculated using a formula that includes factors such as material thickness, bending length, and V-shape die opening width. This formula can be used in conjunction with tonnage charts or calculators, which help estimate the bending force required to achieve bending. Select the appropriate press brake tonnage to prevent tool damage or excessive force, which can damage the worktable or ram. The sinking tonnage limit refers to the time required to embed the punch into the base or ram of the press brake, taking into account the "power flow" through the tool and the maximum tonnage per foot or inch of load. Different metal bending methods require different tonnage. For example, in air bending, the tonnage can be increased or decreased by changing the die opening width. The bending radius affects the opening width of the die. In this case, a method factor must be added to the formula. When using the bottom bending and coining methods, the required tonnage is higher than that of air bending. If the tonnage for bottom bending is calculated, the tonnage per inch of air bending needs to be multiplied by at least five times. If coining is used, even more tonnage may be required than for bottom bending. We have learned that in air bending, the tonnage required decreases as the die opening size increases and increases as the opening size decreases. This is because the width of the die opening determines the internal bending radius, and a smaller die radius requires more tonnage. In air bending, the die ratio is typically 8:1, meaning that the die's opening distance is eight times the material thickness. At this point, the material thickness is equal to the internal bending radius. In air bending, the punch needs to pass over the opening of the bottom die to bend the sheet metal. If the surface of the metal plate is not lubricated, the friction between the die and the sheet metal will increase, requiring more tonnage to bend the sheet metal and reducing the material's springback. Conversely, if the sheet metal surface is smooth and lubricated, the friction between the die and the sheet metal will be reduced, resulting in lower tonnage required for bending the sheet metal. However, this will increase the sheet metal's spring back. The bending speed also affects the tonnage required. As the bending speed increases, the tonnage required decreases. Increasing the speed can also reduce the friction between the die and the sheet metal, but this will also increase the sheet metal's springback. Tonnage is the force applied by the press brake to the metal plate. Therefore, the range of a bending force is determined by the thickness and tensile strength of the sheet metal being bent. One factor is the type of bending material. Different materials have different tensile strengths, which directly affect the amount of force required to bend them. For example, stainless steel typically requires more tonnage than mild steel or aluminum. Tensile strength refers to the maximum stress that a material can bear under a steady load. If this stress is applied and maintained, the material will eventually break. Typical tensile strengths of some materials Another important factor is the thickness of the metal plate. The greater the thickness of the material, the greater the tonnage required, and vice versa. The table shows: The bending length of the press brake workbench is the maximum length that the metal plate can be bent. The bending length of the press brake should be slightly longer than the material to be bent. If the length of the workbench is incorrect, the die or other components may be damaged. The bending load calculator can help determine the required tonnage based on the thickness of the material and other factors, such as bending length and V-shaped opening width. The press brake punch is also a factor to be considered. These punches also have press brake load limits. Right-angle Vee punches can bear a large tonnage load. Due to the slight angle and fewer materials used in the manufacture of acute angle dies, such as gooseneck dies, they are not inclined to withstand heavy loads. When using different dies, their maximum bending force must not be exceeded. In addition, the mold radius and bending radius also affect the tonnage requirements. A larger mold radius may result in an increase in the required bending force. Similarly, larger bending radii may result in higher tonnage requirements. The ratio between the width of the mold opening and the thickness of the material is another factor that needs to be considered. For thinner materials, it is recommended to use a lower mold ratio (e.g. 6 to 1). Thicker materials may require a higher mold ratio (such as 10 to 1 or 12 to 1) to reduce bending force and maintain the application within the capacity of the bending machine. Where: Where: Press brake tonnage can be determined by a press brake tonnage chart. Note: The tonnage in this table is based on the material tensile strength of σbï¼450N/mm2. The value in the table is the bending force when the length of the metal plate is 1m. Where: For example, if S=5mm, V=40(the width of the V die opening is 8-10 times the thickness of the sheet), we can see the value in the chart is 400. From the chart, we can find that bending a 5mm thick and 1m long sheet metal, the tonnage of the press brake is 400KN. Press brake tonnage also can be calculated by the tonnage calculation formula: P=650S²L/V (σbï¼450N/mm²) Where: The calculation result of this formula is approximately equal to the value in the tonnage chart. When the bending materials are different, use the coefficients in the following table to multiply the calculated results. You can use the tonnage calculator below to obtain the results directly. No matter which method you choose to determine the tonnage, make sure not to exceed the tonnage range of the machines and dies. Using the wrong tonnage can damage the die or working components. In the worst case, it can cause deformation of the machine and even jeopardize the safety of the bending operators. When choosing a press brake, it is important to consider the type of material to be bent, as well as its specifications, length, and processing method. These factors will affect the tonnage and dimensions required for your specific project. It is crucial to determine the correct tonnage of the press brake as it affects the overall performance and bending capacity of the machine. To calculate the appropriate tonnage, you can use the press brake tonnage calculator, which takes into account the thickness of the metal plate, bending length, and recommended V-shape die opening width. Another important factor in choosing a press brake is the length of the workpiece. The required length will determine the size of the machine you need. The length of the workpiece should not exceed the maximum length of the machine to ensure an efficient and accurate bending process. Finally, the machine tonnage limit related to the distance between the side frames must be considered. Exceeding the side frame distance limit may damage the machine due to exceeding the machine's centerline load limit. In conclusion, determining the tonnage and load limit of the press brake is essential as it directly impacts the quality of the final product and the longevity of your equipment. Using a press brake with insufficient tonnage can lead to many problems, such as inaccurate bending angles, inconsistent bend lines, and increased spring back. These can result in parts not meeting specifications, leading to costly rework or scrap. On the other hand, using a machine with excessive tonnage can damage the tooling, such as premature wear or breakage of the dies, as well as potentially overloading the machine's frame and hydraulic system. Utilizing the formulas and tools discussed in this article can help you make an informed decision and select a press brake that meets your needs. With over 40 years of experience in the industry, ADH Machine Tool specializes in manufacturing high-quality press brakes designed to deliver precise and reliable bending results. If you're in the market for a new press brake or looking to upgrade your existing equipment, I invite you to browse our product page to explore our range of state-of-the-art machines. Download the Infographic With High Resolution We are the factory to produce kinds of tempered glass products,the cake tray is one of them,it can be clear,picture one and also can be silk printing one.The sizes and packages both can be customized according to your request for it.Our factory produce such products for more than ten years and if you are interested in it,welcome to contact me freely for more information,tks. 25cm Diamter Cake Tray,25cm Diamter Cake Stands,25cm Diamter Clear Glass Cake Tray,25cm Diamter Tempered Glass Cake Tray the shahe city of toughened glass factory , https://www.temperedglasszd.comI. Introduction of Press Brake

II. What Is Press Brake Tonnage

III. Factors that Influence Press Brake Tonnage

Bending Method

Bending Method Effect on Press Brake Tonnage Air Bending It requires more tonnage than air bending because the punch bottoms out in the die. Material contacts the punch tip and die sidewalls. Tonnage is higher but not as high as coining. Bottom Bending It requires more tonnage than air bending because the punch bottoms out in the die. Material contacts the punch tip and die sidewalls. Tonnage is higher, but not as high as coining. Coining Requires the highest tonnage. Punch and die make full contact with the material, compressing and thinning it. Very high force is used to make the material fully conform to the tooling angle Die Width

Friction and Speed

Material Thickness, Tensile strength, and Bending Length

Material Thickness (mm) Bend Radius (mm) Tonnage Multiplier Tonnage Required (tons/m) Mild Steel 1 1 1 10 Mild Steel 2 2 1 40 Mild Steel 3 3 1 90 Aluminum (5052-H32) 1 1 0.45 4.5 Aluminum (5052-H32) 2 2 0.45 18 Aluminum (5052-H32) 3 3 0.45 40.5 Stainless Steel (304) 1 1 1.45 14.5 Stainless Steel (304) 2 2 1.45 58 Stainless Steel (304) 3 3 1.45 130.5 Mild Steel 2 1 1 60 Mild Steel 2 3 1 30 Stainless Steel (304) 2 1 1.45 87 Stainless Steel (304) 2 3 1.45 43.5

Tooling Factor

IV. How To Determine Press Brake Tonnage?

The basic tonnage calculation formula:

Formula considering tensile strength:

Press brake tonnage chart:

V B R S

0.5 0.6 0.8 1 1.2 1.5 2 2.5 3 3.5 4 4.5 5 6 8 10 12 14

4 3 1 41 59

6 4 1 27 39 69 108

8 6 1 29 52 81 117

10 7 2 23 42 65 94 146

12 8 2 35 54 78 122 217

14 10 2 46 67 104 186 290

16 11 3 59 91 163 254

18 13 3 81 144 226 325

20 14 3 130 203 293 398

24 17 4 108 169 244 332 433

28 20 5 145 209 284 371 470

32 23 5 127 183 249 325 411 508

36 25 6 163 221 289 366 451

40 28 7 199 260 329 406 585

45 32 8 177 231 293 361 520

50 35 8 208 263 325 468 832

55 39 9 239 295 425 756

60 42 10 271 390 693 1083

65 46 11 250 360 640 1000

70 49 12 334 594 929

80 57 13 293 520 813 1170

90 64 15 462 722 1040 1416

100 71 17 416 650 936 1274

120 85 20 542 780 1062

V. Choosing the Correct Press Brake

VI. Conclusion